OUR STORY

Grown together with its customers

Grown together with its customers

Founded in the heart of Tuscany in 1983, over time we have grown together with our customers.

From a small company, made up of just three founding partners, we have evolved into an important industrial concern with facilities in Florence and Barcelona.

We have risen to the challenge of today’s markets, expanding our export sales of plastic processing machinery.

The Meccanoplastica brand was born in 1983, although the company had actually been in gestation since 1979, the year in which the three founding partners set up their own business overhauling plastic blow moulding machinery. Armed with 15 years’ experience in the field, acquired as technicians at CO.MEC., one of the first Italian companies active in the design and construction of plastic extrusion blow moulding machines, and full of enthusiasm, the three founders managed to make their dream come true. In 1983 Meccanoplastica entered the Italian market as a company with the capacity to design and build its own innovative machinery for extrusion blow moulding of plastic materials.

The Meccanoplastica brand was born in 1983, although the company had actually been in gestation since 1979, the year in which the three founding partners set up their own business overhauling plastic blow moulding machinery. Armed with 15 years’ experience in the field, acquired as technicians at CO.MEC., one of the first Italian companies active in the design and construction of plastic extrusion blow moulding machines, and full of enthusiasm, the three founders managed to make their dream come true. In 1983 Meccanoplastica entered the Italian market as a company with the capacity to design and build its own innovative machinery for extrusion blow moulding of plastic materials.

After years of research and testing, Meccanoplastica blow moulding machines were the focus of a major technological innovation when electric motors with an inverter on the plasticising unit were introduced in place of variable-speed brush motors. This change allowed considerable energy savings during production cycles

In 1994 Meccanoplastica launched its first multi-layer extrusion blow moulding system. The new 2L machine model MP2/M was fitted with a two-layer extrusion head for producing bottles for the cosmetics industry. With this technology, it is possible to produce small containers with an inner layer in PE and an outer layer in PP, thus obtaining the so-called soft-touch effect that is highly desired in this particular industry

1996 was a decisive year from the export perspective. After the development and growth phase, during which it had focused on the domestic market, Meccanoplastica began to target international customers looking for plastic blow moulding machines.

In 2000 Meccanoplastica received quality certification of its products. Issued by DNV, this certification confirms that they are built in strict compliance with UNI EN ISO 9001 standards.

2002 brought the construction of the first FULL-ELECTRIC injection blow moulding machine. Called JET60, it made Meccanoplastica the first company in Europe to offer a full-electric machine. This technology is particularly sought after in the pharmaceutical sector as it simplifies operations in aseptic production areas.

In 2003 a new headquarters was built. Created for the design, testing and assembly of the ever-growing range of models, the new plant, with a surface area of over 1500 sq. m., allowed the company to double its production capacity.

In 2006, Meccanoplastica obtained a further certification, this time according to the UNI EN ISO 14001 standard, after incorporating environmental protection policies into its corporate quality management system and registering its production site in accordance with the requirements of the European Regulation 761/2001 (EMAS II), subsequently updated as European Regulation 1221/2009 (EMAS III).

In 2011, the company founded Meccanoplastica Ibérica PET Division S.L., based in Barcelona (Spain), and acquired COMEEL Srl, thereby giving rise to the Meccanoplastica Group. The Spanish office looks after the design and construction of full-electric PET preform stretch blow moulding lines. The same year, this facility produced the first mod. MIPET-1P machine, with a single-cavity mould, for the production of PET bottles with a maximum capacity of 2 litres. Comeel Srl specialises in the construction of MECS series systems: blow moulding machines for producing 10- to 25-litre containers and stackable jerry cans.

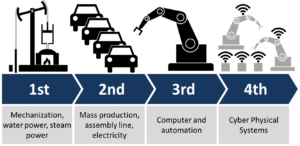

Meccanoplastica is at the forefront of Industry 4.0, which, through interconnectivity of equipment and data flows and opening up new opportunities. Meccanoplastica, adopting a clear conceptual approach, ensures that its full-electric blow moulding solutions incorporate the technological elements and standards that will allow them to operate in 4.0 smart factory environments.

2018 saw the completion of the refurbishment of the Barcelona site. 3000 square meters of equipment were completely renovated with the aim of boosting production capacity and strengthening the company’s commitment to quality, technological development, and the wellbeing of the Group’s people.

Intended as an integral part of the Meccanoplastica Group’s global vision, a new website was launched with a new interface designed to make it easier to find the different blow moulding solutions. The website with a platform allowing multidirectional communication between all stakeholders, is devoted to the Group’s operations, but also takes into account the reality of today’s plastics industry, in which, when its value chain is fully integrated into a circular economy, synergies play a key part in highlighting the economic, social and environmental benefits of plastics.

Meccanoplastica Group makes its contribution, as an activity immediately recognized as essential, by building many Blow Moulding machines that are then used for the production of containers necessary for the use of sanitizing products and thorough deep-cleaning of the person as well as the environments. Activities essential to contain the spread of the Coronavirus infection that has profoundly marked our lives.

A fully electric 4-station IBM machine is built and put into production for the 1st time in the world: it is the JET75-4 of MECCANOPLASTICA Group! Now the Group is a reference partner for Companies operating in the 1st Class Cosmetics-packaging sector.

Meccanoplastica also gives itself a NEW image, with a Logo with innovative and modern colors, but with a shape that is always rooted in tradition. Renewing itself, while remaining tied to its own history, is an essential value for the Group.

Copyright © 2022 Meccanoplastica

P.I. 03307270482

Cap. soc. € 93.600,00

N° Registro Imprese di Firenze (R.I.) 35876